ADVANTAGES:

- Designed based upon widely used and proven Type GK Design (aka Hydril)

- Most widely used annular bop design used in industry

- Only two moving parts

- Long piston style

- Feedable packing unit

- Piston conical bowl design

- Field replaceable wear plate

- Packing flange steel inserts

- Greater stripping capability

- Pressure energized seals

- Seals and parts available worldwide

- Parts and seals interchange with other Type GK BOP’s

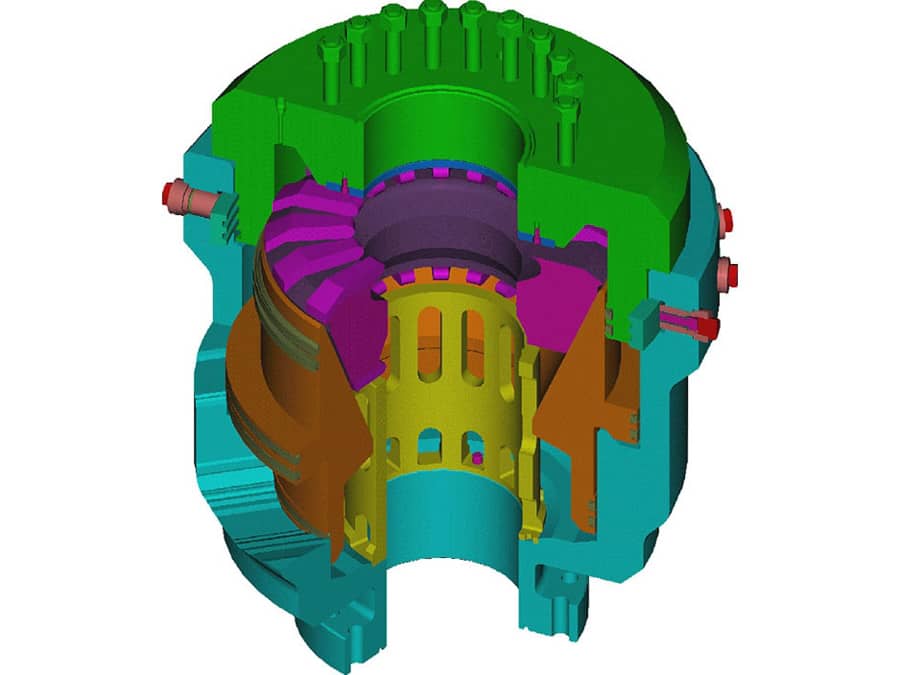

Control Flow Annular BOP’s are particularly qualified to meet the industry’s needs for simple and reliable protection. All Control Flow Annular BOP’s are equipped with a field replaceable wear plate bolted to the inner bottom face of the BOP head. This non-sealing wear surface prevents upward movement of the packing during closure. Further, the packing units are manufactured from high quality rubber material reinforced with flanged steel segments. A full range of annular sizes and pressure ranges are offered in this reliable, time proven design.

SIZE AND PRESSURE RANGES:

CFI Annular GK TYPE (Like GE/Hydril)

- 7-1/16”- 3M/5M/10M (GK TYPE)

- 11”- 3M/5M/10M (GK TYPE)

- 13-5/8”- 3M/5M/10M (GK TYPE)

- 16-3/4”- 5M (GK TYPE)

- 18-3/4”- 10M (GK TYPE)

CFI Annular MSP TYPE

- 20-1/2”- 2M (MSP TYPE)

- 20-3/4”- 3M (MSP TYPE)

- 21-1/4”- 5M (MSP TYPE)

- 29-1/2”- 500psi WP (MSP TYPE)